In the realm of plumbing and infrastructure maintenance, innovations continue to revolutionize traditional methods of repair and renovation. One such advancement is pipe lining – a technique gaining popularity for its efficiency, cost-effectiveness, and minimal disruption compared to traditional pipe replacement methods. In this comprehensive guide, we'll explore the fundamentals of pipe lining, including its process, materials, and benefits, to provide homeowners and property managers with a deeper understanding of this innovative solution.

What is Pipe Lining?

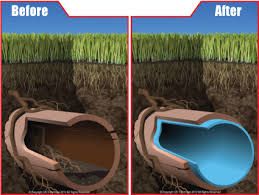

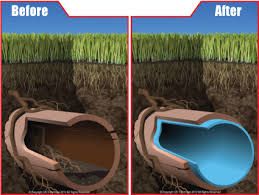

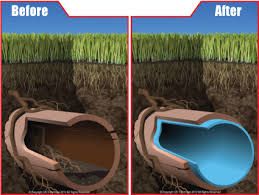

Pipe lining, also known as cured-in-place pipe (CIPP) lining, is a trenchless method used to rehabilitate existing pipelines without the need for extensive excavation. This process involves inserting a flexible resin-coated liner into the damaged pipe and curing it in place, effectively creating a new, seamless pipe within the existing one.

The Pipe Lining Process:

1. Inspection: The process typically begins with a thorough inspection of the existing pipeline using advanced camera technology to identify the extent and location of any damage, such as cracks, corrosion, or leaks.

2. Cleaning: Before lining, the pipe is cleaned using high-pressure water jetting or mechanical methods to remove debris, scale, and other obstructions, ensuring optimal adhesion of the liner.

3. Liner Installation: A flexible liner, typically made of materials like fiberglass or felt, saturated with a specialized resin is inserted into the pipe using inversion or pulling methods, conforming to the shape of the existing pipe.

4. Curing: Once in place, the liner is cured using heat, UV light, or steam, allowing the resin to harden and form a durable, corrosion-resistant lining within the existing pipe.

5. Final Inspection: After curing, a final inspection is conducted to ensure the integrity and quality of the newly lined pipe, verifying that all repairs have been successfully completed.

Materials Used in Pipe Lining:

- Resin: The key component of the lining material, resin formulations vary depending on factors such as pipe material, diameter, and environmental conditions.

- Liner: Flexible liners are typically made of materials like fiberglass, polyester, or PVC, chosen for their durability, flexibility, and compatibility with different pipe materials.

- Curing Agents: Heat, UV light, or steam are commonly used to cure the resin and harden the liner, creating a strong, seamless bond with the existing pipe.

Benefits of Pipe Lining:

1. Cost-Effectiveness: Pipe lining is often more affordable than traditional pipe replacement methods, reducing labor, material, and restoration costs.

2. Minimal Disruption: Trenchless pipe lining minimizes excavation and disruption to landscaping, driveways, and other structures, reducing inconvenience for homeowners and preserving property aesthetics.

3. Durability: Lined pipes are resistant to corrosion, leaks, and root intrusion, providing long-term reliability and extending the lifespan of existing pipelines.

4. Environmental Sustainability: By eliminating the need for excavation and minimizing material usage, pipe lining reduces environmental impact and carbon footprint compared to traditional repair methods.

Conclusion:

Pipe lining offers a modern, efficient solution for rehabilitating aging or damaged pipelines, providing homeowners and property managers with a cost-effective, environmentally sustainable alternative to traditional pipe replacement. By understanding the process, materials, and benefits of pipe lining, individuals can make informed decisions to address their plumbing needs and ensure the longevity and integrity of their infrastructure.